There’s a quiet confidence to Lemay’s arrival in the Middle East — the same steady assurance that has defined the Montreal-founded design firm since its earliest days. Established in 1957, Lemay has grown from a single Canadian studio into one of the country’s most respected global design practices, recognized for shaping cities and communities through an uncommon mix of creativity, technical precision, and human insight.

Today that legacy is finding new expression across the Gulf. From its base in Dubai, Lemay is leading a series of landmark projects in Riyadh, Dammam, Dubai, and Abu Dhabi, marking a significant expansion of the firm’s international footprint. “We’re not simply entering a new market,” says Amro El Chabti, Senior Partner and head of Lemay’s Middle East operations. “We’re already here — trusted, active, and contributing to a region that’s redefining itself in real time.”

A Region on the Rise

Saudi Arabia’s Vision 2030 and the UAE’s drive toward cultural and economic diversification have made the Gulf one of the most dynamic design landscapes in the world. “The appetite for innovation here is real,” El Chabti explains. “Clients want bold, iconic projects that express identity, ambition, and optimism.” He points to the region’s accelerating investment in hospitality, infrastructure, and mixed-use urban districts as evidence that architecture is now central to civic storytelling.

For Lemay, the moment is ideal. The firm’s multidisciplinary model — uniting architecture, interiors, landscape, urban design, structural engineering and environmental expertise under one roof — allows it to respond quickly to complex briefs without sacrificing creativity or craft. “We can adapt to the pace, culture, and climate of each project,” he says. “And each project enriches our global practice: we’re learning as much as we’re contributing.”

Collaboration Without Borders

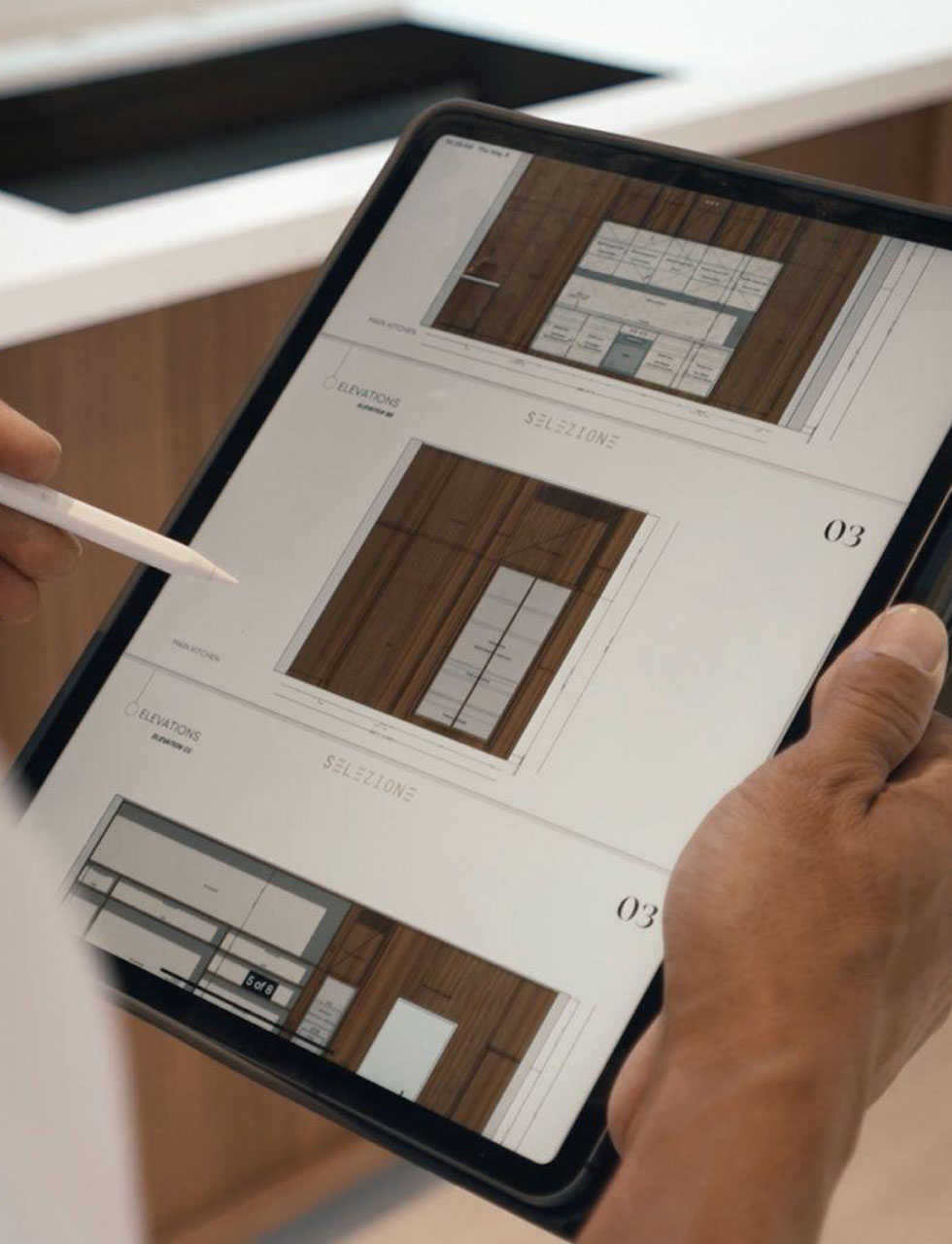

Lemay’s network of studios in America, Europe and the Middle East works as a single creative organism, trading ideas and resources across time zones. Projects begin in one city and evolve in another, drawing on specialists fluent in energy intelligence, cultural planning, and advanced digital design. “Design is never about one office or one person,” El Chabti notes. “It’s about the strength of connection between teams and clients.”

“Design isn’t about distance — it’s about dialogue,” says Amro El Chabti, whose Dubai-based team leads Lemay’s growing portfolio across the Middle East.

That exchange has already delivered results. In less than two years, Lemay has secured multiple high-profile commissions now under construction across the region, from commercial buildings and office space to hospitality amenities and master planning of new neighbourhoods. “When I arrived, people would ask, ‘Who is Lemay?’” he recalls. “Now, we’re delivering work that speaks for itself.”

Building Trust and Presence

Great design emerges from deep relationships: understanding context, listening to communities, and building trust with partners who know the region intimately. “The business rhythm here is fast,” he says. “But earning trust takes time. We build relationships before we build architecture.” That commitment has helped Lemay establish a lasting foothold, with its Dubai studio serving as the regional hub and a growing team taking shape in Riyadh.

Beyond the drawing board, the firm is exploring collaborations with local universities and sustainability partners, extending its belief that architectural practice should leave a broader social and environmental legacy. El Chabti describes the process as incremental but purposeful — a strategy built on listening, adapting, and contributing to the region’s long-term vision.

Looking Ahead

For Lemay, the Middle East represents both opportunity and responsibility: an opportunity to participate in one of the most exciting design markets in the world, and a responsibility to do so with sensitivity to culture, climate, and community. “The goal isn’t just growth,” El Chabti says. “It’s about creating spaces that improve daily life while capturing the spirit of the region.”

As the firm approaches its seventh decade, that spirit of curiosity continues to guide it. “Impactful design results from dialogue,” El Chabti reflects. “It’s that commitment to listening and co-creating that defines our practice.”